产 品 展 示

PRODUCTS

Provide customers with low-priced professional ore products and high-quality and efficient services

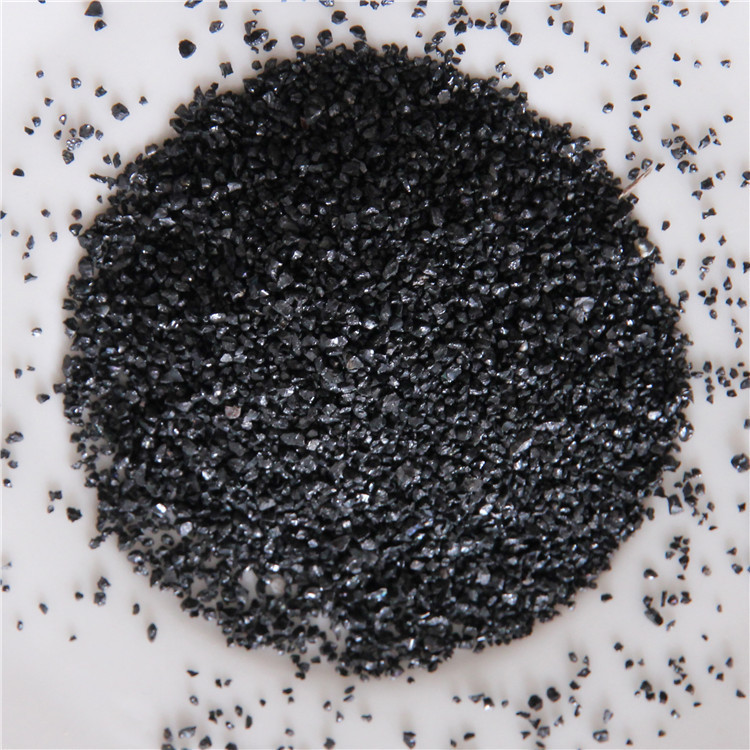

The density of steel slag is greatly affected by the settling velocity of the molten steel in the slag during slag making, generally ranging from 3.1g~ 3.6g/cm ³. The bulk density of steel slag is not only affected by its density but also by its particle size. The volume density of slag powder sieved through an 80 mesh standard sieve is about 1.74g/cm³, with a specific surface area of about 0.32 m²/g and an average pore size of 5.3nm, demonstrating excellent filtration performance. Due to its density and wear resistance, steel slag has a grindability index of 0.96 and a standard sand index of 1, while blast furnace slag has an index of 0.7. Additionally, steel slag is a molten mixture of various metal oxides, making it highly resistant to acid, alkali, and thermal stability.

The chemical properties of steel slag are rich in calcium and silicon, with the main components being CaO, SiO2, Al2O3, FeO, Fe2O3, MgO, P2O5, and fCaO. Due to different production conditions and methods, the composition may fluctuate, and the mineral composition of steel slag is related to its chemical composition, especially depending on the alkalinity of the steel slag. The main components of low alkalinity steel slag are iron oxide, and there are solid solutions of manganese oxide and calcium oxide; The solid solution mainly composed of magnesium oxide, ferrous oxide, and manganese oxide in high alkalinity steel slag. In the mineral composition of steel slag, the content of dicalcium silicate and tricalcium silicate is relatively high, which can preserve high activity; Magnesium oxide exists in low alkalinity steel slag as magnesium roseite mineral, and in high alkalinity steel slag as divalent metal ion oxide, which does not cause poor stability. However, free calcium oxide exists in steel slag of different alkalinity, which can cause pulverization and swelling of the steel slag.

上一个: Emery

下一个: -